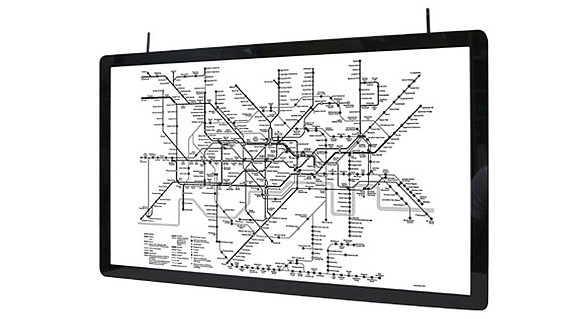

Larger Bonding: VacuBond Optical Bonding now up to 32″

December 16, 2015

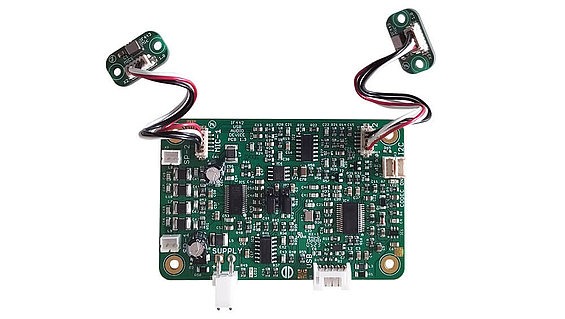

We now can bond AUO’s P320HVN02.1, for example or the transparent P320XVF03.0 easily and with the highest quality. In order to optimize risk management, one machine was installed at the headquarters in Germering and one at our subsidiary Apollo in the USA. So we can sustain production in case of any unforeseeable problems at one location.

In the VacuBond process the various components are bonded together with the high-performance silicone OptoGel in a clean room. The optical bonding fills the air gaps between the individual components and reduces reflection of the incident light on the surfaces by 99 percent. Therefore the readability of the TFT display improves significantly and it offers perfect contrast and color brilliance even when used outdoors and in incident light. In addition, “fogging” is prevented and the shock and vibration absorption is improved significantly.

VacuBond offers many options: whether you want to close open air spaces within the TFT display for use in explosion protected areas (ATEX certification) or you want to bond the pure TFT cell without the bezel into your housing.

Please contact us, we will gladly advise you.